PACKAGING / DISPENSING

At MP Systems we design and construct filling lines with great flexibility for multiple products with different characteristics. Our solutions are ideal for companies that have a wide range of productions and that want to maximise the profitability of their products.

Changing the format is very quick and simple, thereby reducing machine downtime and allowing a variety of containers to be used.

This equipment has been designed for use with liquid filling lines, and can be used with viscous, foamy and conductive liquids.

LINEAR

Suitable for filling liquid and cream products. Depending on the type of product, injection pumps, flowmeters or volumetric cylinders are used. Very quick and easy format change.

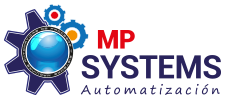

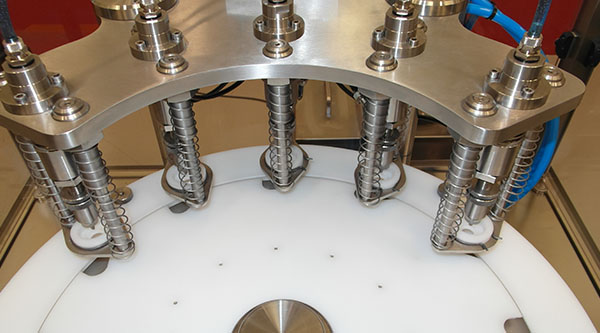

MONOBLOCK

Very versatile machine, suitable for nearly all types of containers. Ideal for very varied production. Includes adjustable stations for dispensing, threading and capping for different formats. Version with “godet” holders for unstable containers.

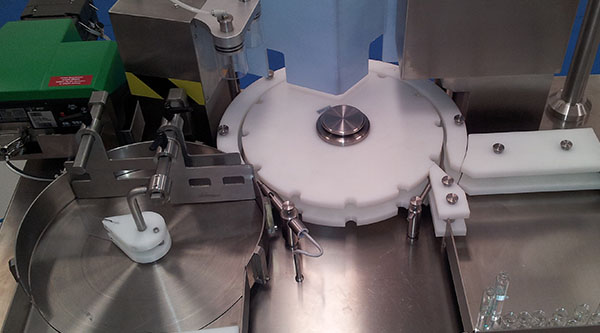

MINIBLOCK

Bench type machine for dispensing into small containers. Versatile and very precise filling. Threading equipment can also be fitted.

SEMIAUTOMATICS

Ideal machines for short and varied productions. Manual dosing adjustment, with the option of fitting a servo motor for automatic adjustment. Tabletop equipment, although it can also be installed on a base plate, on a conveyor belt or fitted into an automatic process.